Choice of Filter Media for Dust Filter Cartridges

1.Before choosing filter media, it is necessary to think about whether the dust is flammable or not. If it is flammable, we suggest to use anti-static filter media or taking other measures to prevent static flash over generating explosion.

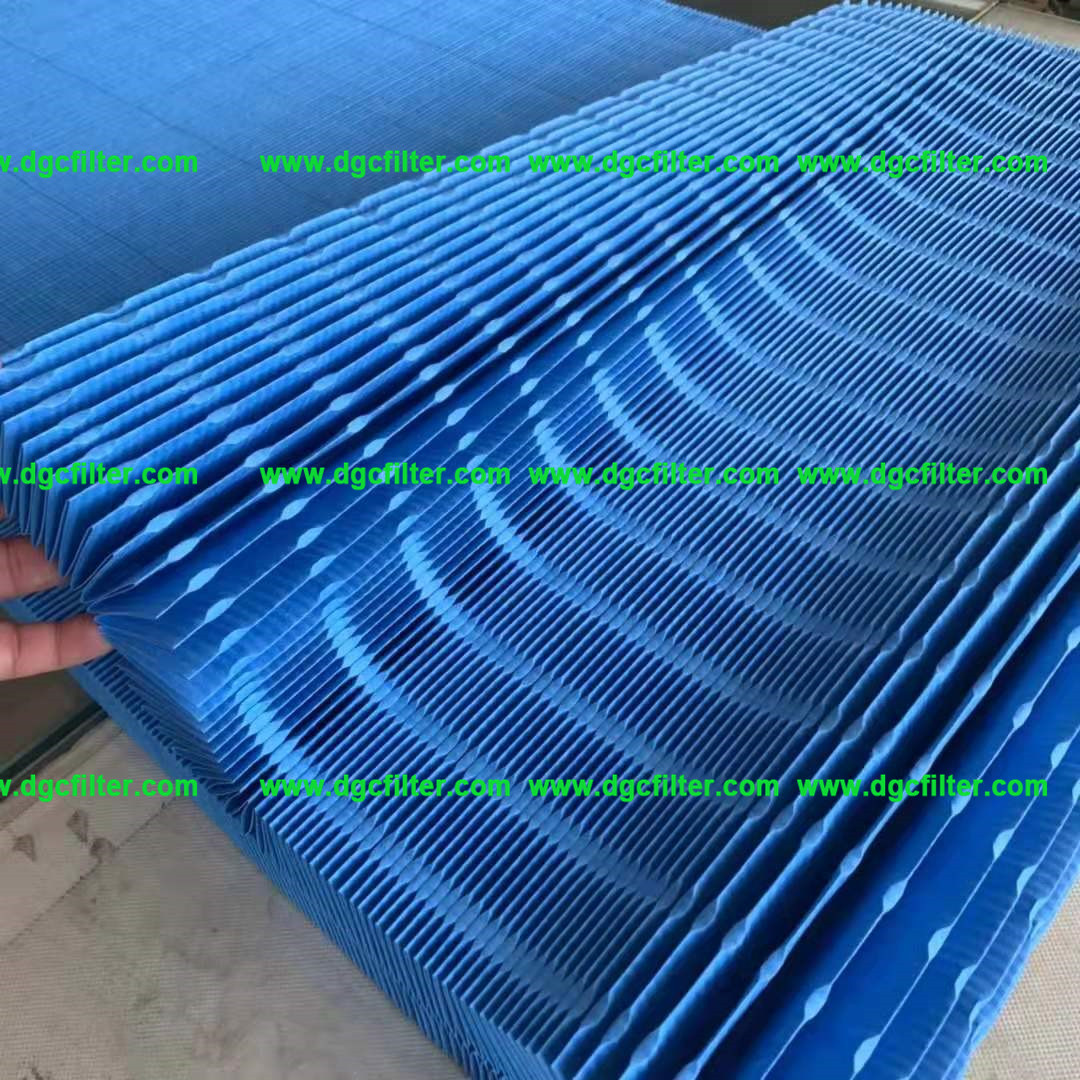

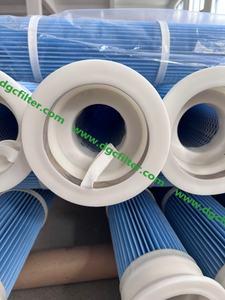

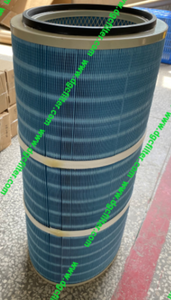

2.As human’s environmentally friendly consciousness growing, dust emission restriction is more and more strict, especially for heavy metal, silicon dioxide, and so on, which damages the human health seriously. Therefore, surface filtration type filter media must be chosen, a kind of filter media with hyper-fine fiber laminated on the surface has advantages as below: high filtration precision, easy for dust-cleaning, low resistance, stable operation, etc.

3.If the working condition is high humidity, dust absorbs moisture easily or dust with oily components, it is recommended to choose filter media that function oil, water, and dirt repellent.

4. If sparks in the system, flame retardant filter media should be used to avoid burning in the filter cartridges (cautious on welding fume treatment).

5.If the dust concentration of dust collectors is very low (such as atmospheric dusting, welding flume, etc.), it is suggested to choose ≤180 g/㎡ thin filter media because it is helpful to increase filter area and flow rate of a single filter cartridge.

6.Working temperature: the working temperature of filter media with main element is polyester materials, is ≤135℃. When polyester nonwoven fabrics are used between 80℃-135℃, the stiffness of fabrics would drop significantly; which makes pleated filter media to stick together easily. In this case, we would adapt some special measures to make the filter media being pleated evenly, and keeping good air permeability.