Dust Collector Bags and Cages

DGC FILTER is a single source for a variety of bags and cages for dust collectors that ensure optimal fit that ensure proper performance.

Achieving optimum filtration performance from a dust collector depends on selecting the proper filter media for the job. We carry a full assortment of high quality filter media and related hardware for all our customers’ dust collectors.

Our media selection allows us to offer solutions for practically any application and for any OEM style baghouse including:

Pulse Jet and Reverse Air baghouse systems

Corrosive gas streams

Challenging particulates

Nuisance collection or product recovery

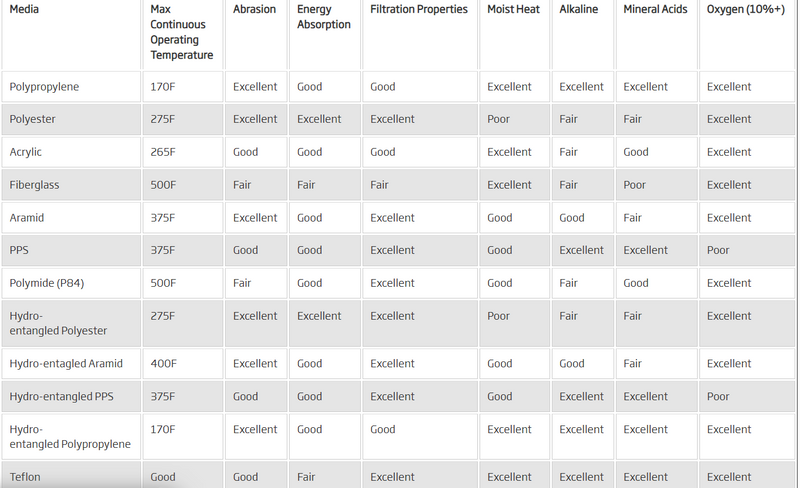

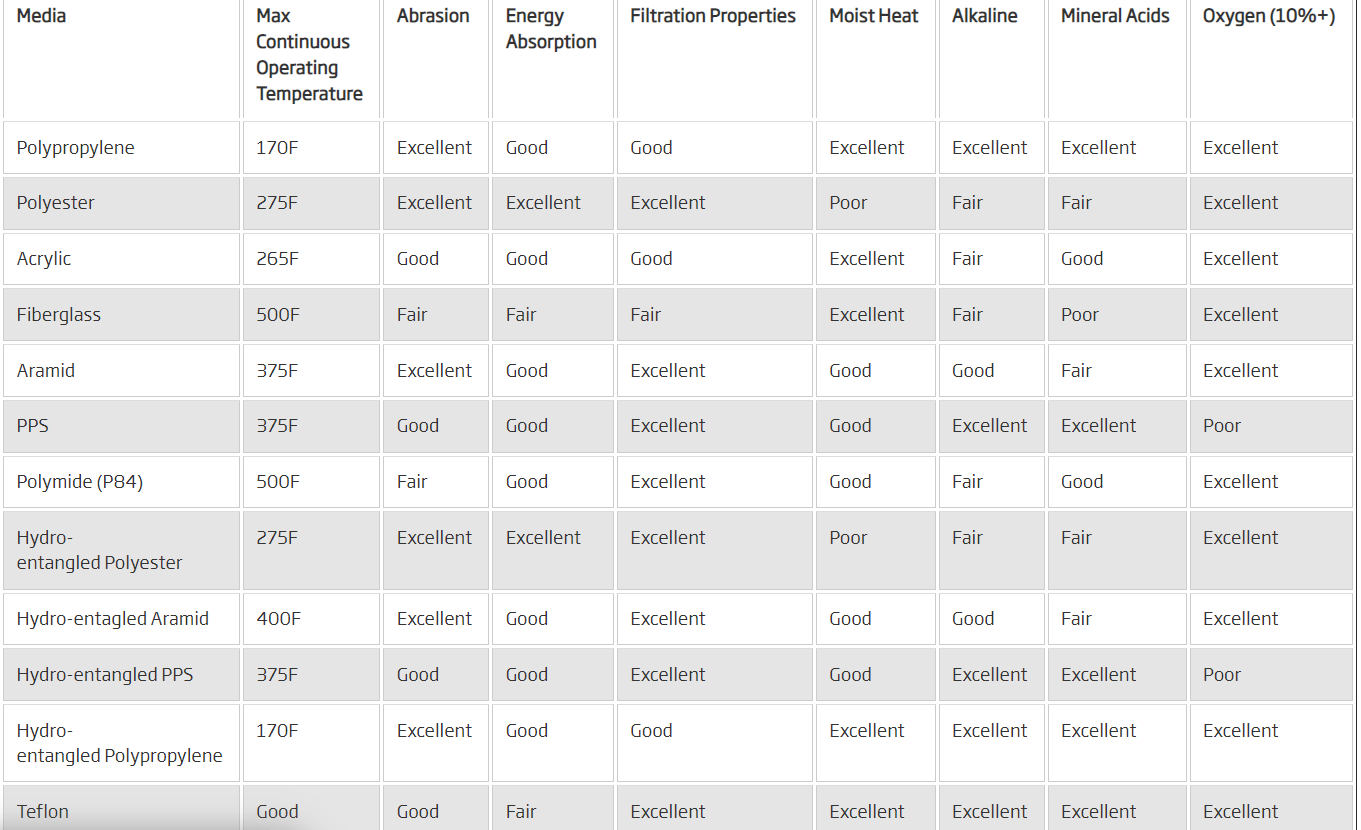

The information that is given below is for your convenience. It serves as a guide for dust collector filter bag applications and specifications. You can reach out to any of our experts with any questions that you may have while selecting your filter bags. If there is any information or application not listed, we suggest that you reach out to our experts and they can assist you.

Pulse Jet Bags

Dry dust applications

Higher air-cloth ratios than shaker or reverse air collector

Dust collected on the outside of the bag

Cleaned through a high pressure blast of compressed air

Cleans each row individually at the same time as other rows are still collecting dust

On-line cleaning

Bag-materials used: Non-woven unless it is for high temperature applications

Pulsaire units with bags up to 26 ft. in length.

Pleated Bags for Pulse Jet Dust Collectors

DGC FILTER’s pleated bags are offering a solution for baghouses that have issues with bottom bag abrasion, low or not enough airflow, high operating pressure drop and high emissions rate.

The pleated bags can be used in any pulse jet dust collectors. DGC FILTER’s pleated filters reduce air-cloth ratios and allow higher airflows with an increased filter area. The filtration area can be increased by 200-300%. Another advantage with DGC FILTER’s pleated bags is direct replacement for the filter bags and cages as well as up to 50% faster and reduced change-out costs and eliminated cage replacement costs. Some benefits from DGC FILTER’s pleated bags are reduced emissions, reduced maintenance, improved dust release and improved filter life.

Reverse Air Bags

Large air volume applications such as wood, metals, etc.

Dust collected on the inside of the bags

Cleaned through a back flush or air and mechanical flexing of the bag fabric

Off-line cleaning

Bag remains open through cleaning because of anti-collapse rings

Bag material used: Woven or light weight non-woven filter bags

Filter Bag Medias:

Polypropylene

Max continuous operating temperature is 170F. Polypropylene is excellent against abrasion, moist heat, excellent resistance to alkalis, mineral acids and applications with more than 15% oxygen content. Polypropylene also has good energy absorption and filtration properties which allows good cake release.

Polyester

Max continuous operating temperature is 275F. Polyester is excellent against abrasion and applications with more than 15% oxygen content. Polyester has good energy absorption and filtration properties and it works fairly well for alkalis depending on the levels of acidity and various mineral acids. Polyester is not a good choice when it comes to moist heat applications. Polyester filter bags are the most commonly used bags because of their strong resistance and stability during various applications. With the large amount of fabric finishes offered for polyester bags makes it a very flexible option.

Acrylic

Max continuous operating temperature is 265F. Acrylic is excellent against moist heat and applications with more than 15% oxygen content. Acrylic also works well against abrasion and mineral acids. Acrylic works fairly well against alkalis and has good energy absorption and filtration properties. Acrylic is a more expensive option that polyester and polypropylene.

Fiberglass

Max continuous operating temperature is 500F, can reach higher temperatures with certain finishes. Contact an expert for more information. Fiberglass is excellent for moist heat applications. Fiberglass is not a good option for mineral acid applications unless a chemical or acid resistant finish is applied to the bags. Fiberglass is a fair option against abrasion and alkalis and is excellent against applications with more than 15% oxygen content. The energy absorption and filtration properties are fair. The fiberglass filter bags are sensitive to bag-to-cage fit. Because of the finishes that are put on fiberglass.

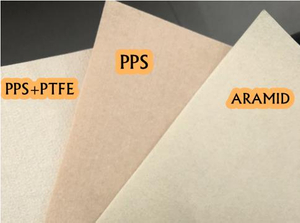

Aramid

Max continuous operating temperature is 375F. Aramid is excellent against abrasion and is good against moist heat and alkalis. Aramid works fairly well towards mineral acid applications. The energy absorption is good and its filtration properties are excellent.

PPS (Polyphenylene Sulfide)

Max continuous operating temperature is 375F. PPS has good abrasion and works well in moist heat applications. Works excellent with alkalis and mineral acid applications. Is not recommended for applications with oxygen content above 15%. The energy absorption is good and the filtration properties are excellent in PPS.

P84 (Polyimide)

Max continuous temperature is 500F and is great choice for high temperature applications such as smelters, asphalt plans and coal-fired boilers. P84 works excellent in applications with over 15% oxygen content. P84 works fair with alkalis and good with mineral acid applications as well as moist heat applications. Energy absorption is good and the filtration properties are excellent in P84. P84 also works fair in high abrasion applications. Must use oversized bags for shrinkage for temperatures above 450F.

Teflon

Max continuous operating temperature is 500F. Teflon is the most expensive option and is mostly used at high temperature applications. Teflon is excellent for moist heat, alkalis and mineral acid applications. Teflon is also excellent for applications with more than 15% oxygen content. Teflon has good energy absorption and fair filtrations properties. Teflon also works good in applications with high abrasion. Must use oversized bags for shrinkage for temperatures above 450F.

Filter Bag Finishes

We offers a variety of fabric filters to best fit your application needs.

Non-Fiberglass

Singe

Purpose: Improved dust cake release

Available for: Polyester, Polypropylene, Acrylic, Aramid, PPS and P-84. (felts)

Glaze

Purpose: Provides a temporary solution for dust cake release. Glaze may reduce airflow.

Available for: Polyester and Polypropylene (felts)

Silicone

Purpose: Provides limited water repellency

Available for: Polyester (felts and woven)

Flame Retardant

Purpose: Helps reduce the intensity of flammable substances but is not flame-proof.

Available for: Polyester and Polypropylene (felts and woven)

Acrylic Coatings (latex base)

Purpose: Improves filtration, efficiency and cake release (may impede flow in certain applications)

Available for: Polyester and Acrylic (felts)

PTFE Surface Treatments and Laminates

Purpose: For capture of fine particulate, improving filtration efficiency and cake release

Available for: Aramid, Polyester, Acrylic, Polypropylene(felt) – Laminates available in Polypropylene, PPS, Polyester and PTFE

PTFE or Fluorocarbon Bath Treatments

Purpose: Water and oil repellency, limited cake release

Available for: Aramid (felt), PE, PP, PPS

ePTFE Membrane

Purpose: Fine particle capture, improved filtration efficiency and cake release

Available for: Cement/lime kilns, incinerators, coal-fired boilers, cupola and ferro/silica alloy furnace

Acid Resistant

Purpose: Improved acid resistance and water retardance

Available for: Aramid (felt)

Fiberglass

ePTFE Membrane

Purpose: Fine particle capture, improved filtration efficiency, cake release and airflow capacity

Applications: Cement/lime kilns, incinerators, coal-fired boilers, cupola and ferro/silica alloy furnace

Silicone, Graphite and Teflon

Purpose: Protects glass yarns from abrasion, adds lubricity

Applications: For non-acidic conditions, primarily for cement and metal foundry applications

Acid Resistant

Purpose: Shields glass from acid attack

Applications: Coal-fired boilers, carbon black, incinerators, cement, industrial and small municipal boiler applications

Teflon B

Purpose : Provides enhanced abrasion resistance and limited chemical resistance

Applications: Industrial and utility base load boilers under mild pH conditions

Chemical Resistant

Purpose: Provides acid resistance and release properties, abrasion resistance, alkaline resistance and improved fiber encapsulation

Applications: Coal-fired boilers (high and low sulfur) for peak load utilities, fluidized bed boilers, carbon black and incinerators