| Advantages of Pleated Filters

For years, Bag Filters have been the staple filtration mechanism for dust collectors. Increasingly these are being to replaced by newer technologies such as Pleated Filter Bags (Or Pleated Media).

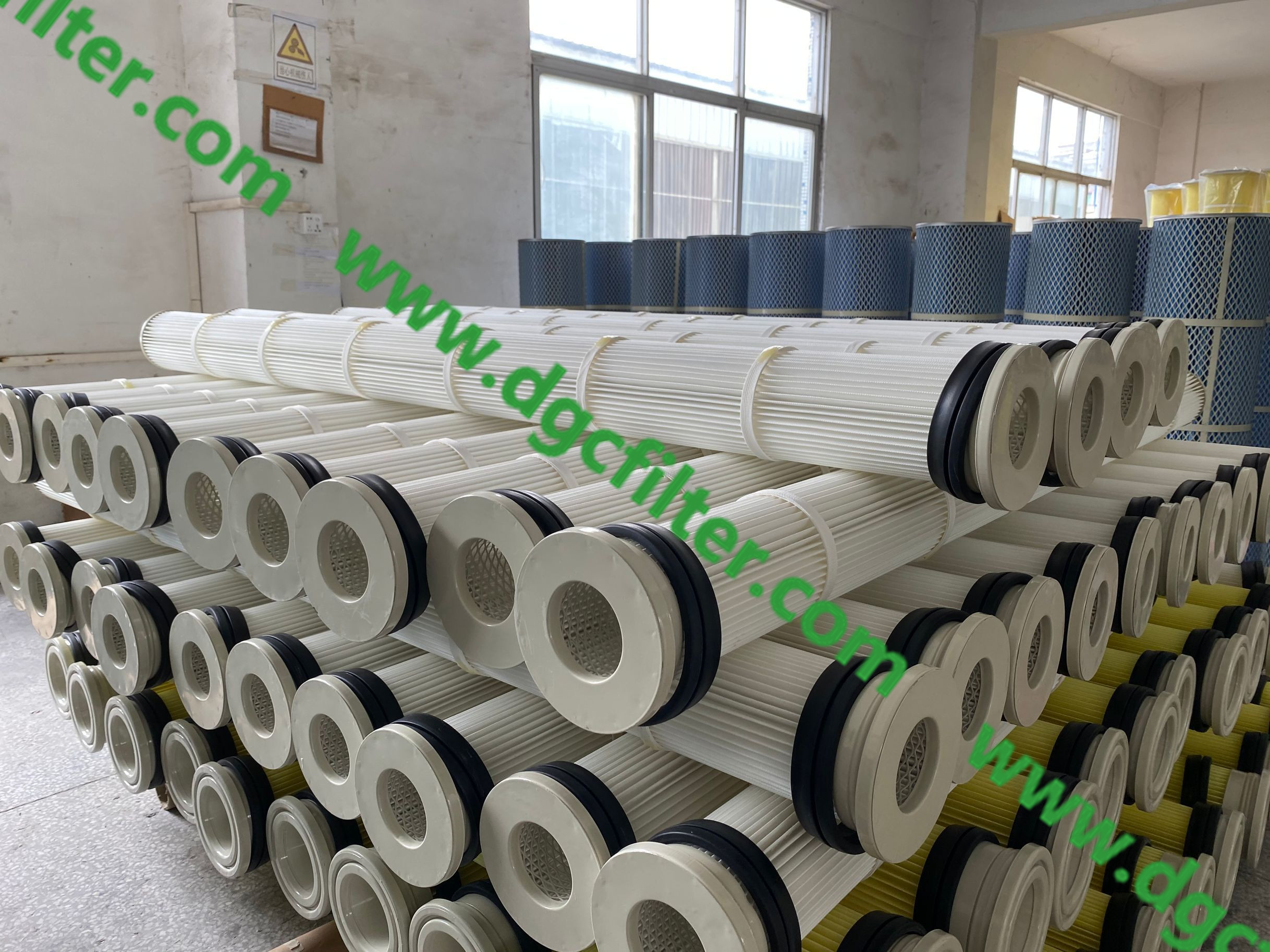

Pleated Filtration Media generally has a few advantages over traditional filter media. The pleats greatly increase filter surface area allowing for lower air to cloth ratios in the same space. Layers of deep pockets made of woven fabric allow for higher dust retention rates. Additionally, with shorter overall bag lengths Pleated Filter Bags remain above the inlet gas stream, reducing abrasion caused by incoming dust particles. Pleated bags are designed to replace fabric bag filters and cages used in many dust collectors.

Often Pleated Filters can be made to fit most existing Baghouses without the need for extensive redesigns. Pleated bags are easily mounted into various size cell plates for both top and bottom load dust collectors. Some of the advantages to switching to pleated media:

Lower Maintenance Costs

Efficiencies up to 99.97%

Higher Air Flow Per Filter Unit

Less Frequent Change-Outs

Better Resistance to Inlet Abrasion

Up to a 5-Fold Increase in Surface Filtration

Washable Exterior

Minimizes Compressed Air Usage

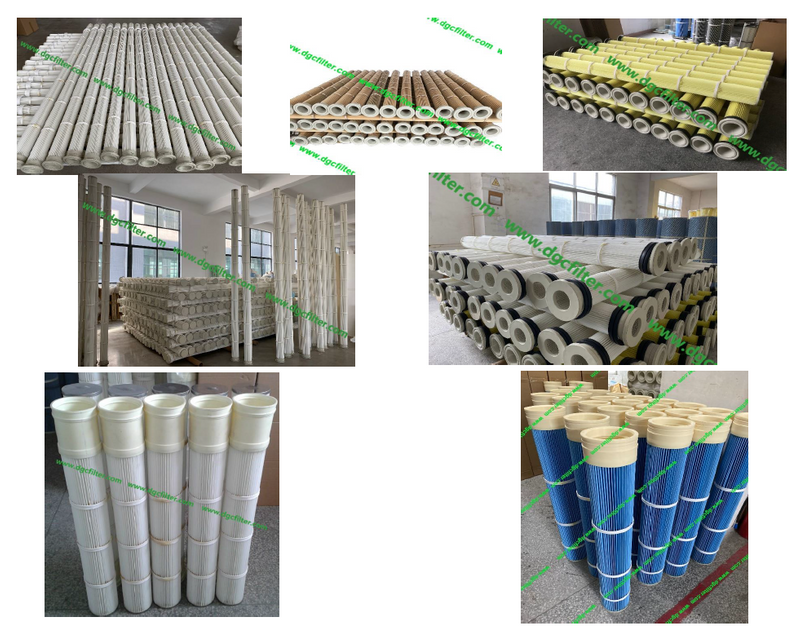

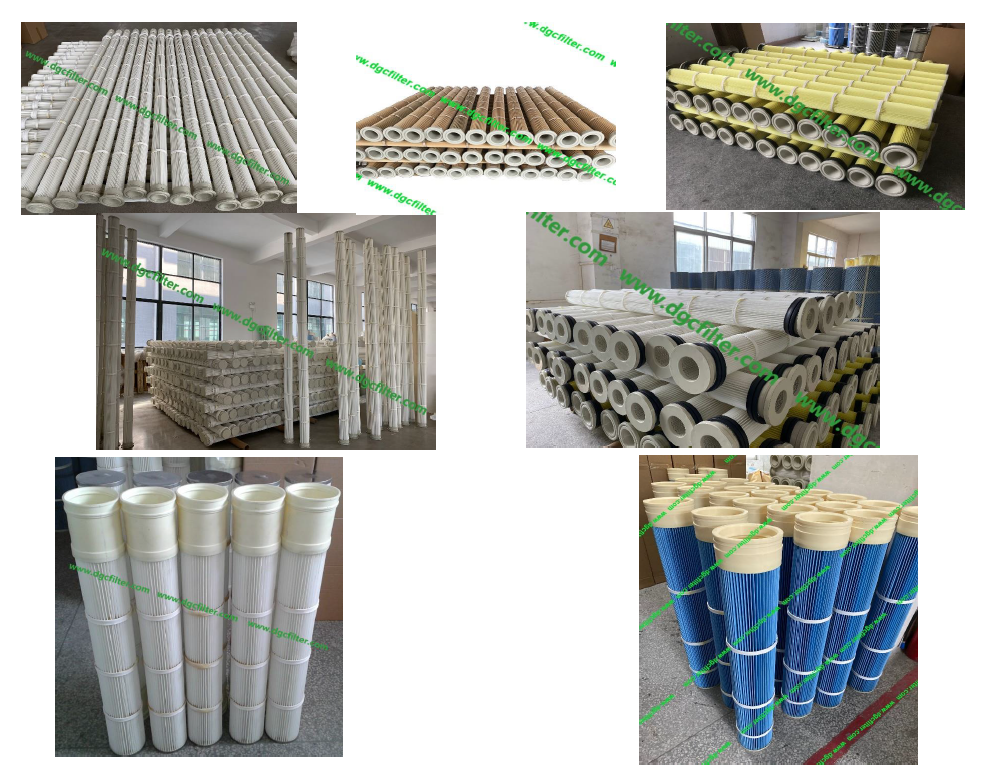

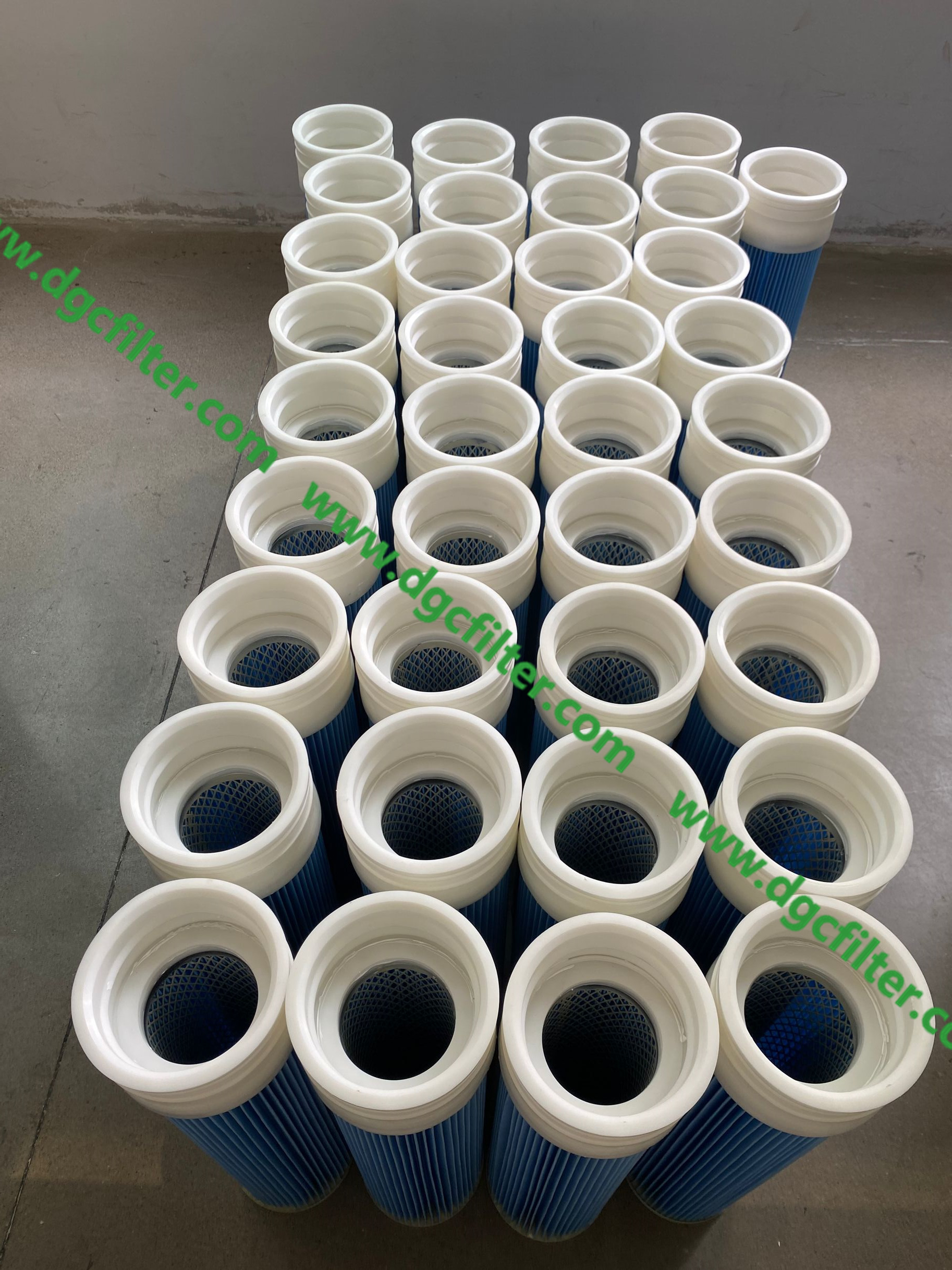

Pleated filters for a baghouse dust collector

Pleated Filters have many advantages over traditional filter methods

| Upgrade Your Existing Dust Collectors Using Pleated Filters

Each year, increasingly stricter environmental regulations are coming into force. These new requirements are beginning to tax many plants already aging dust collection infrastructure. Additionally, many plants are looking to increase productivity, and are forcing their existing system to operate at higher and higher production demands. Usually the simplest solution to this problem is to upgrade to a newer, more efficient dust collection system. However with a sluggish economy causing many to cut back on maintenance expenditures, this often times is not possible. How then, can plant managers and operators keep in compliance with new regulations when they face constantly shrinking budgets?

In certain situations, an alternative to costly rebuilds is to install new pleated filtration media in the existing dust collection system. These filter elements can be designed to fit your current Baghouse tubesheet. Pleated Filtration Media may provide double or triple the filtration area inside your Baghouse, and dramatically reduce your differential pressure and air-to-cloth ratios. This provides increased airflow, reduced cleaning energy costs, and improved performance.